Extreme Freeform

Meet Big Phil, an extreme freeform who has become a legend at Optimax. He is the largest freeform optic fabricated at our facility to date at 585 x 480 x 195 mm in size.

Watch the video below to see Big Phil in action and learn more about how he got his name.

The Challenge

To create a large conformal sensor window. It must keep an aerodynamic shape on a plane or ship to put this window behind a segment on either of these crafts. In order for the optical sensor system to go behind it, it has to be precise, which was the challenge with this project. The size was also an enormous challenge as it would not fit in most commercial systems.

Solution Delivered

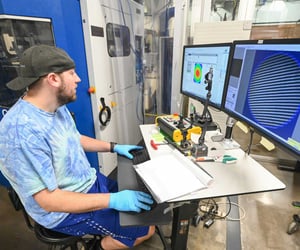

We successfully developed a process to generate, grind, and polish a large conformal window. By leveraging advanced grinding and polishing techniques, we overcame these obstacles to deliver a high-quality, large-scale conformal window with the precision required for optimal sensor functionality.

Engineered Solutions in Action

Pushing Freeform Optical Manufacturing: Fabricating Optimax’s Largest Freeform Component

While manufacturing the largest extreme freeform optic that Optimax has fabricated to date, several issues associated with the size and complex shape of the optic were encountered, including generation and polishing of the part, logistics of moving such a large part around the shop floor, and devising efficient metrology methods. These challenges and solutions will be discussed.

Read More

Learn from the Experts

FABRICATION OF A 500 MM EXTREME FREEFORM CONFORMAL WINDOW

This paper will discuss some of the challenges associated with manufacturing optics of this size and shape and how Optimax solved them. These challenges include: blank acquisition, a lack of viable commercially available polishing platforms for extreme freeform shapes, and metrology. A demonstrator optic was designed and manufactured from fused quartz. Final metrology data for both sides of the window will be shown and discussed.

Fabricating Freeform Optics

Optical designers choose Optimax freeforms for their unmatched quality, reliability, and precision, which help reduce system complexity with smaller, lighter profiles. As a leading producer of freeform optics, we use advanced grinding and smoothing technologies to ensure accuracy and minimal errors. Our proprietary techniques allow us to create high-precision freeforms for UV, Visible, and IR applications with low scatter surfaces, handling even the most challenging projects.

Learn More