Coating Uniformity Correction

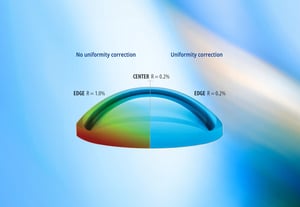

Optimax has developed a deterministic method to correct coating uniformity on large, steeply curved lenses, ensuring consistent spectral performance and high transmission across the entire clear aperture.

For large and steeply curved lenses, an optical coating will be thinner at the edge of the optic unless corrected. For transmitting optics, this non-uniformity can lead to significantly reduced transmission towards the edge of the clear aperture. Optimax has developed a deterministic approach to correct coating uniformity on even the most steeply curved lenses; ensuring good spectral performance and high transmission across the entire clear aperture.

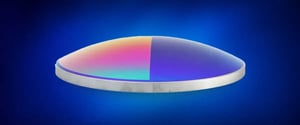

In the optic pictured here, a coated 200mm diameter, 150mm convex radius of curvature lens. The left side of the lens shows the variable reflection from uncorrected coating non-uniformity (multilayer is 15% thinner at edge than the center). The right side shows a uniformity corrected surface; reflectivity is the same from center to edge.

Engineered Solutions in Action

Measurement considerations when specifying optical coatings

Design, specification, and procurement of optical coatings all benefit when the designer has a good understanding of measurement techniques and uncertainties.

Read More

Coating Capabilities

Optimax delivers high-quality optics faster and with less risk by owning the entire manufacturing process, including optical coating. With one of the largest teams of optical engineers, a state-of-the-art facility, and an advanced cleanroom, we reliably meet the most demanding market needs. Our expanding coating capabilities include substrates up to 500mm, IBS coatings, OTR coatings, and low-stress coatings, ensuring innovative solutions for critical challenges.

Learn More