Freeform monolithic multi-surface telescope manufacturing

The Challenge

This is a unique challenge in the surface specification and fabrication requirements, to reduce the amount of alignment time and also to remove potential alignment errors and use.

Solution Delivered

Created a monolithic piece where all of the surfaces were aligned in process. This provides improvements in stability and payload.

Engineered Solutions in Action

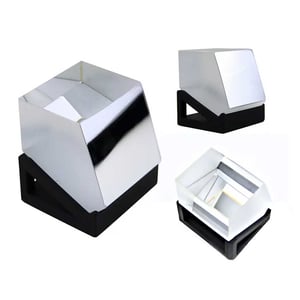

The Manufacturing of a multi-surface monolithic telescope with freeform surfaces

Monolithic multi-surface telescopes combined with freeform optical surfaces provide improvements in optical performance in a smaller footprint as compared to systems with spherical surfaces, while providing superior mechanical stability to traditional telescope assemblies.

Read More

Learn From The Experts

The Manufacturing of a Multi-surface Monolithic Telescope with Freeform Surfaces

Monolithic multi-surface telescopes combined with freeform optical surfaces provide improvements in optical performance in a smaller footprint as compared to systems with spherical surfaces, while providing superior mechanical stability to traditional telescope assemblies. Three different monolithic telescope concepts, in different configurations and optical performance were produced as proof of concepts. The results of the telescopes are presented as well as the unique manufacturing and testing challenges to produce these monolithic optical systems.

Fabricating Freeform Optics

At Optimax, our precision engineering and measurement capabilities allow us to tolerance strict limits for freeform surfaces, enabling the generation of mild, wild, and extreme surfaces. We work to ensure our collaborations are innovatively driven, meaning we are continuously looking for new ways to measure, specify, and tolerance freeform surfaces.

Learn More