Aspheric Optics

Optical systems integrators rely on Optimax for high-quality aspheric lenses with precise focusing properties, leveraging one of the industry's largest teams of technical experts.

Our unique expertise in specifying, manufacturing, and testing aspheres helps optical designers overcome aberrations, reduce system size, and enhance efficiency. This results in innovative, compact optical setups and strong collaborative partnerships that add maximum value for end-users.

What is an Asphere?

An asphere is an optical element with one or more aspheric surfaces – a complex surface with non-constant curvature. These unique geometries can impart superior performance to optical systems by mitigating spherical aberrations. For imaging systems, aspheres enable clearer, sharper images. Additionally, a single aspheric optic can often be used instead of multiple optical elements, allowing for smaller and lighter systems.

Our aspherical lenses enable optical designers to overcome the intrinsic aberrations associated with spherical lenses, and to reduce system size and weight, ultimately leading to optical setups that are more compact and efficient than conventional systems. Optimax specializes in manufacturing high-quality aspheric lenses; leading the way with unmatched investment in cutting-edge equipment and testing, this allows us to develop deeply collaborative partnerships with our customers, adding maximum value to end-users.

Specifying Aspheric Optics

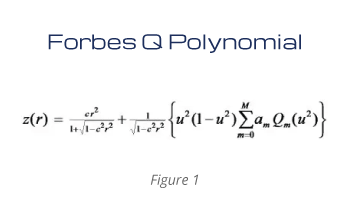

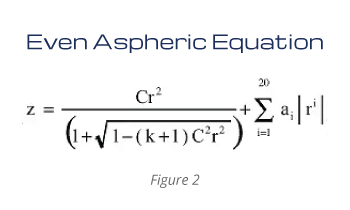

Specifying an asphere begins with a custom aspheric form, often fit to the Forbes Q Polynomial (Figure 1) or the Even Aspheric Equation (Figure 2).

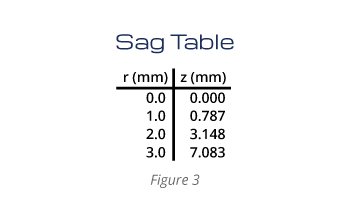

Describing the form involves specifying Vertex Radius (I/C). Conic Constant (k) and applicable Aspheric Coefficients (a). Including a Sag Table (Figure 3) provides reference information to check correct data entry for each manufacturing or metrology tool used. We accept asphere designs from our customers in manufacturing drawing format or by optical design software files (preferably, Zemax).

Our team is well versed in providing manufacturability feedback and providing cost and lead time trade-offs for various tolerancing schemes. If you have a question about your design, don’t hesitate to contact Optimax.

Manufacturing Aspheric Lenses

Our optics manufacturing expertise is built on the depth of our advanced metrology capabilities. As the saying goes, "If you can’t measure it, you can’t make it." We offer a full range of metrology solutions, from industry-standard tools to custom Optimax systems, including interferometric test setups, stitching interferometry, non-contact and contact profilometers, and high-precision CMM instruments.

Complementing these metrology tools is an array of cutting-edge manufacturing platforms, both industry-standard, and Optimax-engineered, for aspheric grinding, polishing, deterministic finishing, and smoothing. This combination ensures we deliver precision aspheres with minimal limitations and maximum quality.

FIND THE OPTIC SPECIFICATIONS RIGHT FOR YOUR NEEDS:

Manufacturing the Future

At Optimax, we manufacture the future by delivering the highest precision optics with speed and reduced risk. By owning the complete manufacturing process, including optical coating, and leveraging one of the largest teams of optical engineers with state-of-the-art facilities, we provide our customers with high-quality optics and expedited delivery.

Submit an RFQ to begin your partnership with one of the world’s leading custom optics manufacturers, committed to long-term customer success.