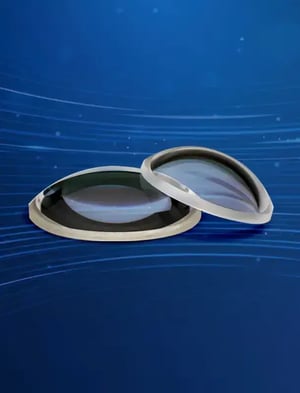

Optical Coatings

Optimax delivers finished optics faster and with less risk because we own the complete manufacturing process, including optical coating. Our customers choose us because we can reliably deliver the highest quality optics at expedited timeframes and with reduced risk, because we not only have one of the largest teams of optical engineers and state-of-the-art manufacturing facility and technologies at our disposal but because we own the entire manufacturing process. This includes an advanced cleanroom where we routinely generate coatings for some of the most demanding markets on earth.

With a continuously expanding coating facility and a solutions-based approach to optical coatings, we have overcome a range of critical issues for our customers. We can coat substrates up to 500mm with capabilities extending into the directed energy market (IBS coatings), OTR coatings, and low-stress coatings.

What are our Coating Capabilities?

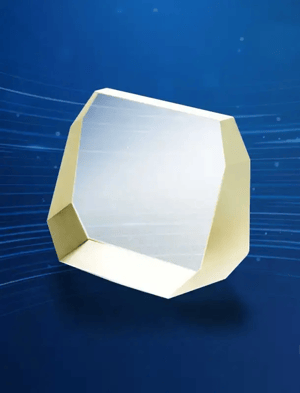

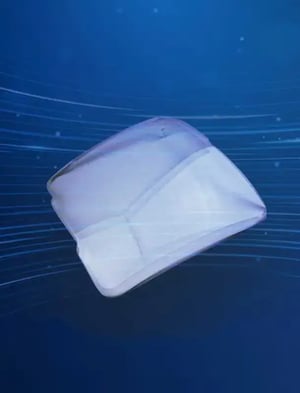

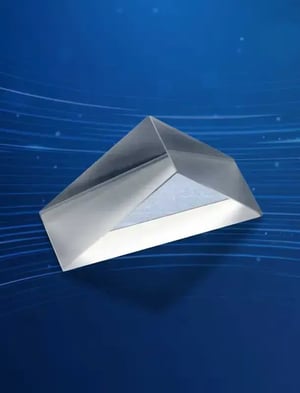

We produce custom anti-reflection coatings with diameter up to 500mm; beamsplitters; metal mirrors; laser line and broadband dielectric mirrors; filters and polarizers. We produce functional coatings for the full spectrum, from DUV to mid-IR applications. Our coatings have been used successfully in some of the most demanding space, defense, high-power laser (HPL), medical, and semiconductor applications. Learn more about the industries we serve.

TECHNOLOGY

- E-beam & thermal evaporation

- Plasma ion-assisted deposition

- Ion Beam Sputtering (IBS)

- Thickness uniformity control

- FEA coating stress analysis

METROLOGY

- High dynamic range spectrophotometer

- Photothermal common-path interferometry

- Cavity ring-down loss and reflectivity

- Deep ultraviolet life testing

- Laser damage testing

FIND THE OPTIC SPECIFICATIONS RIGHT FOR YOUR NEEDS:

Engineered Solutions

Types of Optics

Optimax is a world-class manufacturer of precision optics. Our capabilities incorporate a wide range of manufacturing technologies from which we can engineer solutions that best fit your requirements. Fabrication capabilities range from conventional machinery to highly deterministic CNC machining.

Applications of Optical Coatings

Optical engineers must go through a detailed decision-making process when designing high-precision optical components. At Optimax, we have years of experience supporting manufacturing teams in critical application areas with high-performance optical coatings that stand up to the harshest operating conditions. We consider the needs of our valued customers at every step of the fabrication process and strive to deliver optical coatings that go beyond standard specifications.

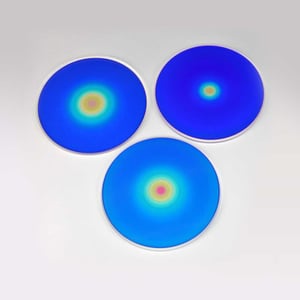

CW High Power Laser Coatings

Our continuous and pulsed wavelength (CW/PW) high-power laser coatings have been applied in some of the world’s most demanding CW laser systems, offering a laser damage threshold of >10 MW/cm2 plus low defect counts and low absorption.

**Max peak absorption as measured using Photothermal Common-Path Interferometry at Optimax, 2 mm scan length. Measurements verified by Stanford Photothermal Solutions.

Pulsed High Energy Laser Coatings

Thousands of Optimax coated optics are used in the highest-energy pulsed lasers in the world. Our coating and cleaning processes have been developed under the National Ignition Facility and Omega Laser guidelines to achieve low defect counts, low absorption, and high laser damage thresholds.

**Max peak absorption as measured using Photothermal Common-Path Interferometry at Optimax, 2 mm scan length. Measurements verified by Stanford Photothermal Solutions.

UV/DUV Lithography Coatings

We have also developed highly uniform filters for ultraviolet and deep ultraviolet (UV/DUV) lithography applications, supplying the world's lithographic engineers with optical substrates qualified for more than a billion cycles of KrF illumination with no spectral degradation.

Space Qualified Coatings

Space can be a harsh environment for optical coatings. Our engineering team has successfully provided antireflection (AR) coatings for a wide range of space applications. Our coatings have been qualified for many missions, demonstrating:

- Stable transmission after extended radiation exposure

- Stable spectral performance in the cold vacuum of space

- Good adhesion and durability after extended humidity and temperature cycling

Learn From The Experts

Explore the Optimax Knowledge Center for access to technical papers, charts, tools, and videos designed to support your optical manufacturing needs.Manufacturing the Future

At Optimax, we manufacture the future by delivering the highest precision optics with speed and reduced risk. By owning the complete manufacturing process, including optical coating, and leveraging one of the largest teams of optical engineers with state-of-the-art facilities, we provide our customers with high-quality optics and expedited delivery.

Submit an RFQ to begin your partnership with one of the world’s leading custom optics manufacturers, committed to long-term customer success.

.webp?width=300&name=About-Careers2%20(1).webp)