Freeform Lens

Optical designers and integrators choose Optimax freeforms because our quality and reliability are second to none. We offer high-precision freeform optical shapes that have small footprints and lighter profiles, enabling reduced system complexity.

With an expansive team of technical experts, Optimax is one of the largest leading producers of freeform optics, combining optimal grinding and smoothing technologies to fabricate precise components with positional and mid-spatial frequency errors.

This allows us to take on the most challenging projects and we can generate high-precision freeforms for UV, Visible, and IR applications using proprietary techniques for low-scatter surfaces.

What are Freeform Optics?

FLATS / PLANOS

No curvature

Radial symmetry

SPHERES

Constant radius

Radial symmetry

ASPHERES

Varying radius

Radial symmetry

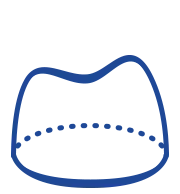

FREEFORMS

Non-constant curvature

Little to no symmetry

Specifying Freeform Optics

Freeform optical shapes or surfaces are designed with little to no symmetry. As with highly complex aspheres, freeform optical design is influenced by local slope change and surface form, particularly when it comes to the complexity of the shape and the manufacturing process used. Freeform optical shapes are typically more complex than aspheres and are considered by many to be the next generation for optical systems. The experienced team of optical fabricators at Optimax can work with equations, cloud of points, and/or robust 3D models. Although the demands of freeform optical manufacturing are extremely complicated, we have years of experience and accumulated technical know-how at our disposal. We are uniquely capable of rapidly delivering as specified freeforms with complex geometries in small, lightweight formats.

Manufacturing Freeform Optics

Our precision engineering and measurement capabilities allow us to tolerance strict limits for freeform surfaces, enabling the generation of mild, wild, and extreme surfaces. At Optimax, we work to ensure our collaborations are innovatively driven, meaning we are continuously looking for new ways to measure, specify, and tolerance freeform surfaces.

Learn more about the careful consideration given to manufacturing tolerances, the iterative process of deriving those tolerances, and general freeform manufacturing limits.

FIND THE OPTIC SPECIFICATIONS RIGHT FOR YOUR NEEDS:

Manufacturing the Future

At Optimax, we are manufacturing the future, creating the highest precision optics underlying high-tech systems in key markets and applications. We offer rapid and expedited delivery upon request and are committed to our customers in the long term.

Submit an RFQ to start building your relationship with one of the world’s foremost manufacturers of custom optics.