Metrology Optics

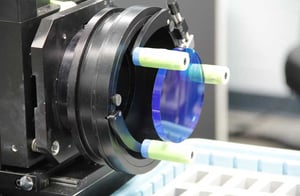

High-precision optical metrology is central to the Optimax approach. We deploy cutting-edge optical measuring systems to ensure our manufacturing processes yield the highest quality optics to exacting customer specifications. We are uniquely set to measure and certify optics to extremely tight tolerances, with an array of measuring devices.

Key measurement tools at our disposal include custom interferometer setups and surface profilers which enable us to measure an expansive range of critical properties with absolute precision. With unmatched experience in the science of measurement for optical components, we offer a wide range of measurement options. We are well-versed in specific quality control standards and routinely provide inspection data records with each optical component to guarantee customer satisfaction.

Why is Optical Metrology important?

Optical metrology is the study of measurement using light. It is often preferable to mechanical metrology due to its greater accuracy, versatility, and ability to profile delicate workpieces. An optician’s ability to finish an optical surface is often limited by metrology. Measuring the specific attributes of a lens to known certainties establishes lens quality, which creates value for the customer. Reliable inspection data, therefore, removes unknowns in optical system modeling and performance. At Optimax, we run a continuous improvement program for quality assurance to identify measurement uncertainties and minimize their impact upon optics inspection.

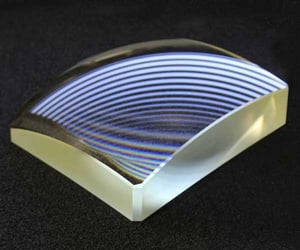

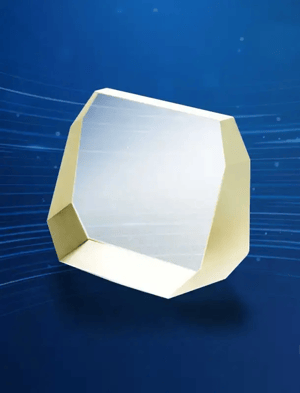

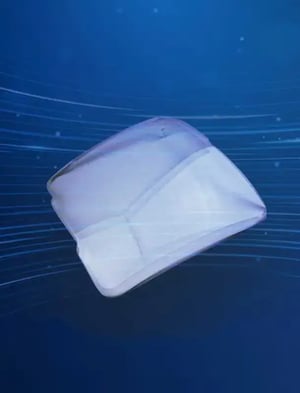

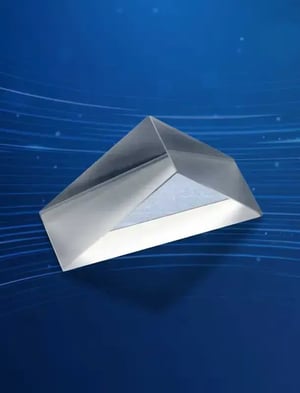

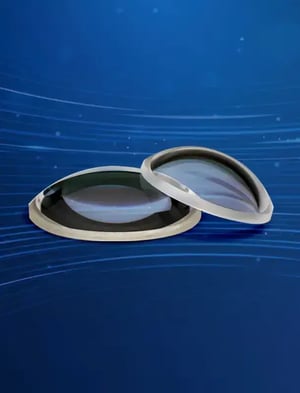

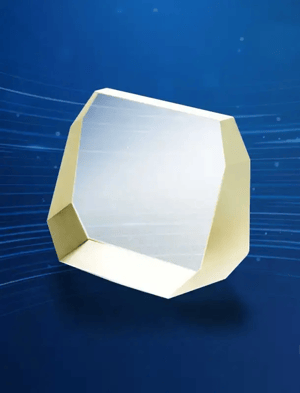

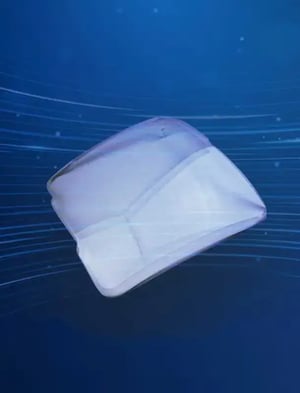

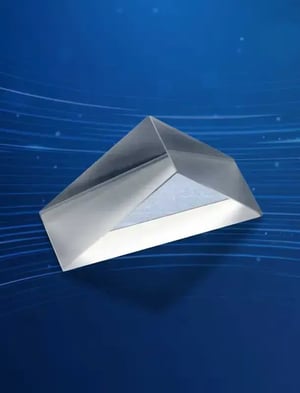

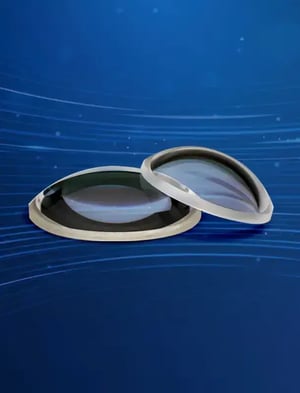

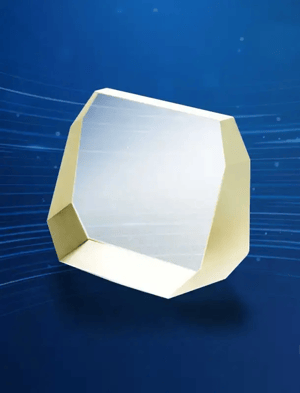

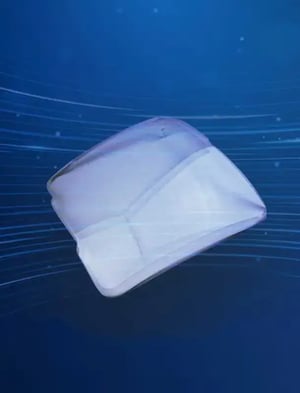

Types of Optics

Optimax is a world-class manufacturer of precision optics. Our capabilities incorporate a wide range of manufacturing technologies from which we can engineer solutions that best fit your requirements. Fabrication capabilities range from conventional machinery to highly deterministic CNC machining.

Technology

Our approach to optical precision focuses on continual innovation and using the most specialized tools available. We have a suite of industrial metrology solutions to meet the most extreme measurement needs. These include: precision standard fizeau interferometers for irregularity measurements in spherical and plano surfaces; surface profilers for non-spherical surfaces (i.e. aspheres), and stitching interferometers to measure multiple zones on a lens surface, then mathematically stitch the data together to determine irregularity over the full aperture.

The new Optimax Metrology Laboratory provides the best possible environment for precision optical measurements. With extreme vibration isolation and temperature control, the facility is intended for measuring high-precision optical components to accuracies better than 50th wave. Additionally, specialized software tools that measure irregularity for comparison to a Zernike fit specification are available to optical designers for measurement analysis.

Manufacturing the Future

At Optimax, we are manufacturing the future, creating the highest precision optics underlying high-tech systems in key markets and applications. We offer rapid and expedited delivery upon request and are committed to our customers in the long term.

Submit an RFQ to start building your relationship with one of the world’s foremost manufacturers of custom optics.