Optical Prisms

OEMs benefit from Optimax’s unmatched expertise in delivering precision-engineered solutions, allowing us to tackle challenges beyond the capabilities of other manufacturers.

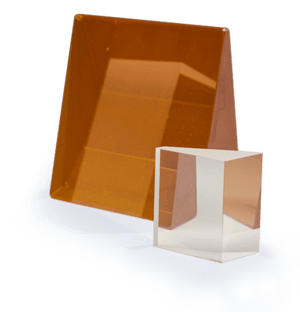

Optical prisms, often a costly bottleneck due to their geometric complexity and tight tolerances, are no exception. Optimax confidently commits to one-week delivery for various prisms, including dispersion prisms, blocks, and mirror substrates and specializes in fabricating prisms up to 300 mm in diameter, with reliable prototype generation available upon request.

An Introduction to Optical Prisms

Optical prisms differ from traditional lenses in that they lack both a spherical surface and an axis of symmetry. Instead, they consist of two or more nominally plano surfaces separated by a wedge angle. This alters the terminology used to define and specify optical prisms and typically increases production time due to the added complexity and the need for precision finishing on multiple sides.

The significance of these geometries lies in their ability to reflect or refract light, enabling functions such as dispersion, deflection, reflection, and rotation. These capabilities are essential for critical applications in dual-channel instruments, anamorphic systems, imaging systems, and any application requiring beam steering or image manipulation.

Specifying Optical Prisms

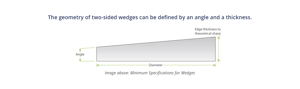

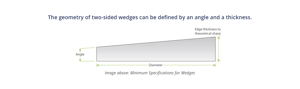

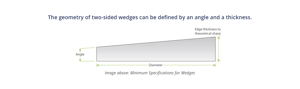

Optical prisms vary significantly in size, shape, and the number of surfaces. Defining the part geometry requires careful selection of directly measurable physical parameters, such as the linear dimensions of the plano surfaces to the theoretical sharps (the intersection points that would exist if the corners were not beveled). Manufacturers must also specify part thickness, which is the depth of separation between the two plano surfaces at a single point on the optic. At Optimax, we typically specify the thickest edge for ease of measurement but can also specify the centerline thickness or thinnest edge when necessary.

Manufacturing Optical Prisms

At Optimax, we specialize in manufacturing optical prisms up to 300 mm in diameter, and with our state-of-the-art grinding and smoothing technologies, can deliver prisms in a variety of complex geometries to tightly-defined surface flatness.

Routinely fabricated prisms:

- Blocks

- Brewsters

- Cubes

- Doves

- Polygons

- Rhomboids

- Right angles

Common functions include:

- Alignment aides

- Beam splitting/folding

- Grating substrates

- Light pipes

- Mirror substrates

FIND THE OPTIC SPECIFICATIONS RIGHT FOR YOUR NEEDS:

Manufacturing the Future

At Optimax, we manufacture the future by delivering the highest precision optics with speed and reduced risk. By owning the complete manufacturing process, including optical coating, and leveraging one of the largest teams of optical engineers with state-of-the-art facilities, we provide our customers with high-quality optics and expedited delivery.

Submit an RFQ to begin your partnership with one of the world’s leading custom optics manufacturers, committed to long-term customer success.