Products & Capabilities

Optical systems integrators rely on Optimax to deliver high-quality optical components to the most precise manufacturing requirements using the right technology and know-how. We have one of the largest teams of technical experts in the industry, with years of experience tackling critical issues in lens manufacturing. Our unique expertise in specifying, manufacturing, tolerancing, and measuring optical components helps us lead the way in the industry with unmatched investment in cutting-edge equipment and testing. We strive to develop deeply collaborative partnerships with our customers, adding maximum value to end-users.

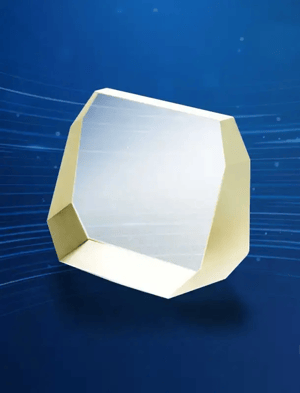

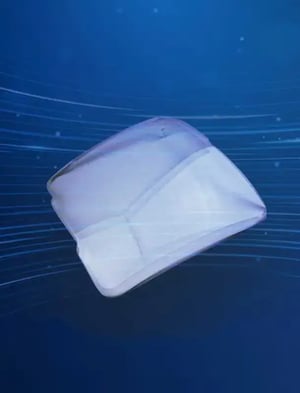

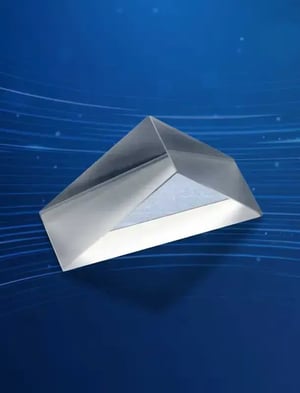

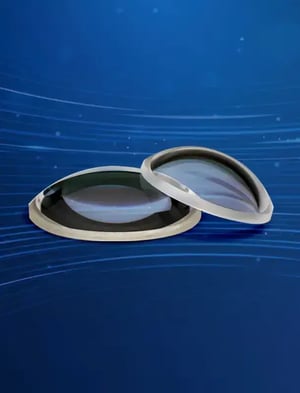

Types of Optics

As a world-class precision optics manufacturer, Optimax combines diverse fabrication techniques to meet your specific requirements. Our capabilities span from conventional machines to highly precise CNC technology.

MANUFACTURING ―

LIMITS

- Diameter 5 MM to 600 MM

- Wavelengths 193nm to 12um

TOLERANCES

- Consult the Manufacturing Tolerance Chart

FABRICATION ―

TECHNOLOGY

- CNC and traditional polishing

- Magnetorheological finishing and Ion Beam figuring

- Robotic polishing and smoothing

- 5-axis ultrasonic milling and light-weighting

METROLOGY

- 6 environmentally isolated metrology labs

- Full-aperture stitching interferometry

- Broad spatial frequency coverage

- Zeiss Zenos CMM

Optics Capabilities

Optimax creates optics for breakthrough aerospace, defense, semiconductors, and medical device technologies. Our manufacturing groups enable us to deliver complex optics with the speed your programs require efficiently.

What are our Coating Capabilities?

We produce custom anti-reflection coatings with diameter up to 500mm; beamsplitters; metal mirrors; laser line and broadband dielectric mirrors; filters and polarizers. We produce functional coatings for the full spectrum, from DUV to mid-IR applications. Our coatings have been used successfully in some of the most demanding space, defense, high-power laser (HPL), medical, and semiconductor applications. Learn more about the industries we serve.

TECHNOLOGY

- E-beam & thermal evaporation

- Plasma ion-assisted deposition

- Ion Beam Sputtering (IBS)

- Thickness uniformity control

- FEA coating stress analysis

METROLOGY

- High dynamic range spectrophotometer

- Photothermal common-path interferometry

- Cavity ring-down loss and reflectivity

- Deep ultraviolet life testing

- Laser damage testing

Optimax Buying Process

With years of expertise in lean manufacturing, Optimax ensures fast, on-time deliveries. As the world’s leading rapid-delivery manufacturer of custom optical components, we guide you through every step to create the perfect solution for your needs.

Manufacturing the Future

At Optimax, we manufacture the future by delivering the highest precision optics with speed and reduced risk. By owning the complete manufacturing process, including optical coating, and leveraging one of the largest teams of optical engineers with state-of-the-art facilities, we provide our customers with high-quality optics and expedited delivery.

Submit an RFQ to begin your partnership with one of the world’s leading custom optics manufacturers, committed to long-term customer success.