All Technical Papers

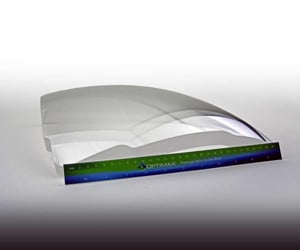

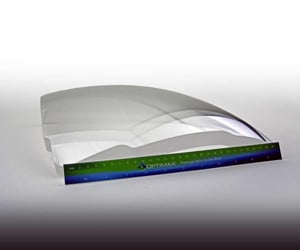

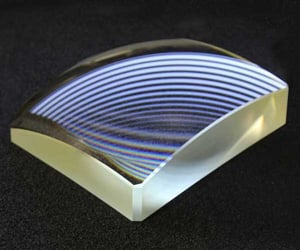

Optimax has developed a fabrication process that not only reduces cost but also aids in producing spherical sapphire components to better figure quality.

Read More

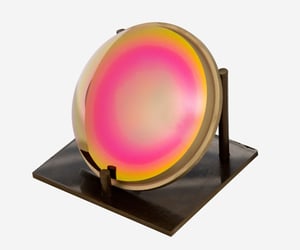

This paper is an introduction to the specification and tolerancing of Mid-spatial frequency (MSF) ripple or waviness.

Read More

The cost of lenses is strongly dependent on the difference between the specified tolerances and the limits of the optics manufacturer, the coater, and the metrologist.

Read More

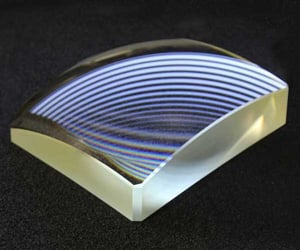

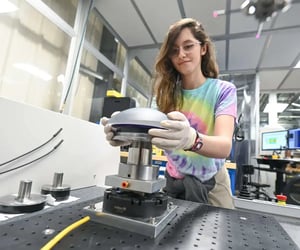

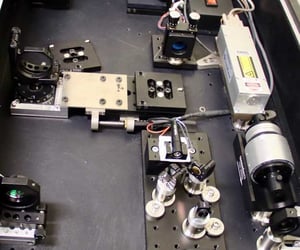

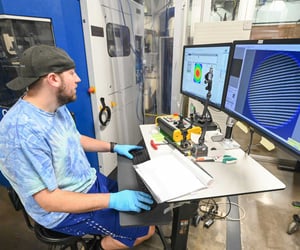

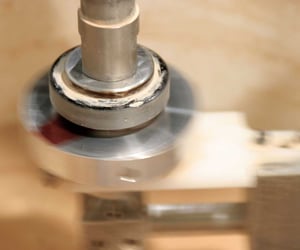

The concept for polishing optical elements with a process called VIBE is presented, application to non uniformly sloped optics such as aspheric shapes is detailed, and initial results on spherical surfaces are presented.

Read More

Two main paths for tolerancing spherical radii are power tolerance and linear radius tolerance. Both measure change relative to a nominal value, but the metrology used is the key difference.

Read More

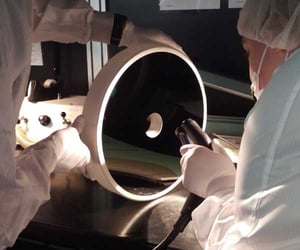

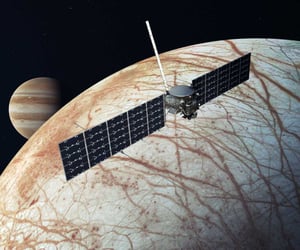

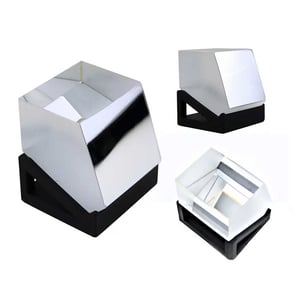

Monolithic multi-surface telescopes combined with freeform optical surfaces provide improvements in optical performance in a smaller footprint as compared to systems with spherical surfaces, while providing superior mechanical stability to traditional telescope assemblies

Read More