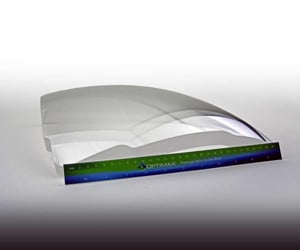

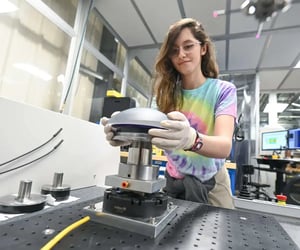

Lens Tolerancing & Inspection

High-precision optical metrology is central to the Optimax approach. Our cutting-edge optical measuring systems, ensure our manufacturing processes yield the highest quality optics to exacting customer specifications. Read our collection of technical papers on lends tolerancing and lens inspection by Optimax today. Learn more about lenses today.

Read More

How to use manufacturing statistics when tolerancing a lens systemLens design software analyzes optical tolerances by modeling a perturbed optical system to capture the effect of simultaneous changes in manufacturing and...Read More

Read More

Considerations in Manufacturing Cemented AssembliesOne design strategy for an optical system is centering two or more lenses together to build a lens assembly. However, strain in excess may cause...Read More

Read More

Optical Glass: Substitutes Versus EquivalentsSelecting the material from which a lens is made is a fundamental design consideration. In certain situations, a substitute or equivalent material may need...Read More

Read More

Specifying And Measuring Spherical Surface Irregularity ©This paper will define surface irregularity for spherical surfaces, offer information on measurement methods for testing surface irregularities, and some...Read More

Read More

Mechanical Attributes: Diameter, Center, and Edge Thickness Specification for Lens ManufactureMechanical attribute tolerances can be a major cost driver because of time and yield penalties added to the fabrication of a lens. Dimensions and their...Read More

Read More

Specifying and Measuring Slope Error of Optical SurfaceThis paper will first detail where slope error originated from, what it represents, and the role it plays in the optical performance.Read More

Read More

Role of Surface Roughness In Optical PerformanceThis paper examines the role surface roughness plays in optical system performance, discusses the components of a surface roughness specification, and...Read More